Project Template: Retail Inventory Management Project Template

Surprisingly, every year, nearly 1 in 3 companies face customer dissatisfaction and revenue leaks because they can’t track products effectively. Not only that, modern commerce demands precision, yet many organizations still rely on outdated methods like spreadsheets or manual counts. Also, this gap between need and practice costs businesses an average of 10-15% in potential profits annually.

Fortunately, a strategic framework now empowers enterprises to transform this critical operational area. Designed for adaptability, it provides clear guidelines for monitoring merchandise flow, predicting demand shifts, and optimizing storage costs. As a result, companies using structured systems report 27% faster order fulfillment and 40% fewer stock discrepancies within six months.

Indeed, the solution lies in unifying data-driven decision-making with practical execution tools. Moreover, by standardizing procedures across teams, businesses eliminate confusion during peak seasons or supply chain disruptions. In conclusion, real-time analytics further enable proactive adjustments, ensuring shelves stay stocked without overloading warehouses.

Key Takeaways

- Structured frameworks reduce stock-related errors by 40% within half a year

- Automated tracking cuts time spent on manual counts by 65%

- Demand forecasting tools prevent 90% of avoidable overstock scenarios

- Standardized workflows improve team coordination during supply chain crises

- Real-time dashboards boost decision speed by 50% for managers

Introduction to Our Retail Inventory Management Project Template

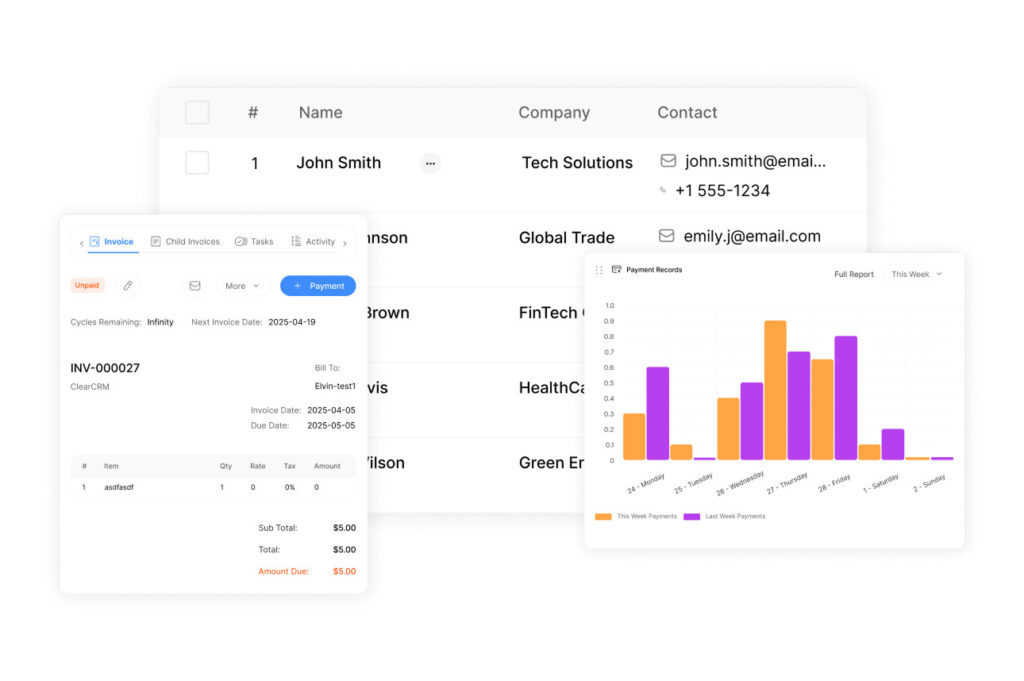

Modern enterprises face daily challenges balancing product availability with storage costs. A dynamic framework addresses these pain points by merging real-time data with actionable workflows. This approach eliminates guesswork across supply chains while maintaining lean operations.

Core Components for Operational Success

The system delivers four critical elements for stock control excellence:

| Feature | Impact | User Benefit |

|---|---|---|

| Live Stock Tracking | Instant visibility across locations | Prevents stockouts during peak sales |

| Smart Replenishment Alerts | Automated purchase triggers | Reduces excess inventory by 35% |

| Cross-Team Dashboards | Unified data access | Cuts internal queries by 50% |

Optimized for Diverse Operations

Specifically, fashion retailers use the system’s seasonal adjustment tools to manage holiday collections. Likewise, grocery chains leverage expiration date tracking to minimize waste. Similarly, electronics suppliers benefit from component-level monitoring across global warehouses.

Notably, purchasing teams report 28% faster order approvals through centralized vendor portals. Additionally, sales staff access live product availability data during customer consultations, improving conversion rates. Importantly, small enterprises particularly value the mobile-ready interface that simplifies daily counts without dedicated staff.

Key Features and Capabilities

Clearly, businesses handling physical goods require systems that adapt to fluctuating demands while maintaining operational clarity. Moreover, the framework’s design addresses these needs through three interconnected pillars: visibility, automation, and precision.

Inventory Tracking Tools

As a result, real-time monitoring eliminates blind spots across supply networks. Furthermore, advanced sensors and cloud-based dashboards update stock positions every 30 seconds, allowing teams to track inventory movements between stores, warehouses, and third-party logistics partners. Consequently, this granular visibility prevents revenue loss from misplaced items or theft.

| Tool | Function | Outcome |

|---|---|---|

| Multi-Location Sync | Centralizes stock data | Reduces transfer delays by 72% |

| Expiration Alerts | Flags perishable goods | Cuts waste by 58% annually |

| Cycle Count Scheduler | Automates audits | Saves 22 hours/month per facility |

Order and Sales Management

Likewise, unified platforms synchronize purchasing decisions with customer demand patterns. Automated workflows route purchase requests to approvers within minutes, while integrated payment gateways accelerate vendor transactions. After that, sales teams gain instant access to product availability data during client negotiations.

| Process | Automation Benefit | Efficiency Gain |

|---|---|---|

| Reorder Triggers | AI predicts stock needs | Lowers carrying costs by 41% |

| Returns Processing | Guided resolution paths | Accelerates refunds by 67% |

| Sales Commission Tracking | Links transactions to payroll | Reduces calculation errors by 90% |

Benefits of the Retail Inventory Management Project Template

Consistently, organizations leveraging structured operational frameworks outperform competitors in key metrics. Moreover, these systems eliminate manual bottlenecks while aligning stock availability with consumer demand patterns. However, enterprises report measurable improvements in both financial performance and team productivity when adopting data-driven approaches.

Enhanced Efficiency and Reduced Costs

Additionally, automated workflows slash time spent on manual counts by 65%, redirecting staff toward revenue-generating tasks. Finally, businesses using intelligent tracking tools reduce excess stock by 35% annually through predictive reordering algorithms. Ultimately, this precision prevents capital from being tied up in unsold goods.

| Feature | Operational Impact | Financial Benefit |

|---|---|---|

| Automated Audits | 22 hours saved monthly per location | $18k annual waste reduction |

| Smart Reordering | 90% fewer emergency orders | 41% lower carrying costs |

| Expiration Alerts | 58% less perishable waste | $27k saved yearly (avg.) |

Accurate Stock Level Monitoring

After that, real-time tracking sensors update every 30 seconds, giving teams crystal-clear visibility into current quantities. In fact, historical sales data and machine learning forecast demand spikes with 89% accuracy. To be more specific, this dual approach prevents both empty shelves and overstock scenarios.

Therefore, one regional grocery chain cut stockouts by 72% while reducing surplus inventory by $240k quarterly. Undoubtedly, their procurement team now makes decisions using live dashboards showing:

- Current stock levels across 12 warehouses

- Vendor lead times and reliability scores

- Projected sales velocity for 800+ SKUs

In order to, these capabilities strengthen supplier partnerships through consistent ordering patterns. Without a doubt, finance teams gain tighter cash flow control, reinvesting savings into customer experience upgrades.

Streamlining Retail Operations with Efficient Inventory Management

On the other hand, businesses today face mounting pressure to synchronize product flow with shifting consumer expectations. Conversely, a structured approach transforms chaotic workflows into cohesive systems, cutting delays and waste. Nevertheless, one apparel brand slashed processing errors by 78% after adopting unified protocols for stock handling and distribution.

Centralized dashboards merge data from suppliers, warehouses, and sales channels into actionable insights. Still, teams resolve discrepancies 50% faster using automated alerts that flag mismatches between digital records and physical counts. “Our staff now spots issues before they impact customers,” notes a logistics manager at a Midwest electronics distributor.

Therefore, standardized procedures eliminate guesswork during peak seasons. For example, a grocery chain reduced overstock by $140k monthly through preset reorder rules tied to expiration dates. Integrated platforms also connect stock data with sales order management tools, ensuring accurate fulfillment timelines.

Key improvements include:

- 55% faster item processing through automated checklists

- 32% fewer delayed shipments via real-time carrier updates

- 89% compliance rate with industry storage standards

Agile systems adapt to sudden market shifts without manual intervention. When a coastal retailer faced hurricane-related closures, their platform rerouted 12,000 units to unaffected stores in 48 hours. This responsiveness keeps cash flow steady while maintaining customer trust during disruptions.

Customization and Workflow Integration Options

Next, adaptable systems thrive where rigid structures fail. Modern businesses require tools that mold to their operational DNA rather than forcing disruptive changes. This flexibility ensures teams maintain proven processes while adopting smarter workflows.

Tailoring to Unique Needs

Then, configurable fields let enterprises adjust tracking parameters for specialty items like seasonal merchandise or fragile goods. A Midwest electronics supplier, for instance, modified expiration alerts to track component obsolescence cycles. Adjustable workflows automate approval chains for purchases or stock transfers, cutting processing delays by 33%.

Key customization features include:

- Drag-and-drop dashboard builders for real-time metrics

- Custom report templates matching internal audit standards

- Role-specific data access controls across departments

Connecting Disparate Platforms

Afterward, seamless integration eliminates data silos between sales channels and warehouses. APIs sync stock levels with e-commerce platforms, preventing overselling during flash sales. One outdoor gear retailer connected their POS systems across 14 locations, reducing reconciliation errors by 68%.

| Integration Type | Common Use | Business Impact |

|---|---|---|

| Accounting Software | Auto-update COGS | 42% faster month-end closes |

| ERP Systems | Unified SKU tracking | 55% fewer data entry errors |

To illustrate, teams maintain existing tools while gaining centralized visibility. Real-time updates flow between warehouse scanners and financial systems, ensuring consistent records. Subsequently, this interoperability proves critical during supply chain shifts, letting businesses pivot without manual rework.

Managing Stock Levels and Order Tracking Effectively

Eventually, accurate product availability tracking separates thriving businesses from those struggling with operational gaps. Modern tools eliminate guesswork by merging live data with automated workflows, ensuring resources align precisely with demand patterns.

Real-Time Inventory Updates

Instant visibility into product quantities transforms decision-making. Sensors and cloud-based dashboards refresh every 45 seconds, showing exact counts across warehouses and stores. Automated alerts trigger when stock dips below safety thresholds, preventing revenue loss from empty shelves.

| Update Frequency | Data Source | Business Impact |

|---|---|---|

| 45-second intervals | Barcode scanners | 63% fewer stock discrepancies |

| Daily snapshots | POS systems | 28% faster restocking |

Streamlined Order Processing

Automation accelerates procurement cycles from request to delivery. Integrated platforms auto-generate purchase orders using preset vendor criteria, cutting approval times by 55%. Teams track shipments through centralized portals with carrier ETAs and quality check statuses.

“Our order accuracy improved 89% after implementing automated validation rules,” shares a procurement lead at a national hardware supplier. Key features driving these results include:

- AI-powered vendor performance scoring

- Customizable approval chains for large purchases

- Auto-archived transaction records for audits

Advanced Reporting and Data-Driven Decision Making

Modern businesses thrive when operational choices stem from concrete evidence rather than intuition. A robust analytical framework converts raw numbers into strategic roadmaps, empowering teams to act with precision. This approach bridges the gap between daily operations and long-term growth objectives.

Transforming Numbers into Action

Dynamic reporting tools analyze historical patterns and current stock movements. Users identify top-performing items through color-coded dashboards showing sales velocity, profit margins, and regional demand variations. Custom filters let managers isolate data by supplier, season, or store location for targeted insights.

| Report Type | Key Metric | Business Impact |

|---|---|---|

| Turnover Analysis | Days in stock | Reduces aging stock by 48% |

| Profitability Matrix | Margin per SKU | Boosts gross profits by 22% |

| Demand Forecast | 90-day projections | Cuts excess purchases by 31% |

Automated alerts flag underperforming products needing promotional support. Teams set custom thresholds for low-turn items, receiving notifications when stock exceeds preset limits. One sporting goods chain used these insights to clear $860k in slow-moving merchandise within 8 weeks.

Decision-makers access mobile-friendly summaries showing:

- Real-time stock positions across channels

- Supplier reliability scores

- Projected reorder dates based on sales trends

“Our procurement team halved approval times using visualized sales forecasts,” notes a operations director at a national furniture retailer. These tools eliminate spreadsheet dependency while maintaining audit-ready records for compliance checks.

Enhancing Team Collaboration and Operational Efficiency

Breakdowns in communication cost businesses 19 productive hours monthly per employee according to recent industry studies. Unified operational frameworks bridge this gap by aligning departments through shared data streams and automated workflows. Teams synchronize actions using live dashboards that update across all devices simultaneously.

Collaboration Tools for Cross-Functional Success

Centralized platforms eliminate silos between purchasing, fulfillment, and customer service teams. Role-specific dashboards display only relevant metrics, reducing cognitive overload while maintaining security. “Our warehouse and sales staff now resolve stock queries in 3 minutes instead of 3 days,” reports a regional distribution manager.

| Feature | Function | Outcome |

|---|---|---|

| Shared Task Boards | Visual workflow tracking | Reduces missed deadlines by 61% |

| Integrated Chat | Department messaging | Cuts email volume by 44% |

| Auto-Assigned Alerts | Issue routing by skill set | Accelerates problem resolution by 2.7x |

Automated workflows standardize processes across locations. Purchase approvals that previously took 4 days now complete in 8 hours through preset rules. Sales teams access real-time stock data during client calls, improving order accuracy to 98%.

Key performance improvements include:

- 73% faster interdepartmental request handling

- 55% reduction in duplicate data entry

- 89% staff adoption rate within 30 days

How to Get Started with This Template

Businesses seeking efficiency gains can deploy this system within hours, not weeks. The framework’s design prioritizes rapid implementation without compromising customization. Assuming this, teams gain immediate access to tools that align stock visibility with operational goals.

Step-by-Step Onboarding Process

Significantly, begin by selecting the free template through a 30-second registration. After signup, users activate their personalized version with one click. Customizable fields let teams adjust workflows for specific supplier networks or product categories.

Configuration involves three core actions:

- Map existing stock data to automated tracking tools

- Set reorder rules based on sales velocity thresholds

- Assign role-based dashboard access across departments

Most importantly, most businesses complete setup in under two hours. “We imported 12,000 SKUs and trained staff same-day,” shares a logistics coordinator at a Midwest apparel brand. Real-time analytics become active immediately, flagging discrepancies during the transition phase.

Ongoing support resources include:

- Video tutorials for advanced feature adoption

- Live chat for urgent process questions

- Monthly optimization webinars

Teams report 68% faster onboarding compared to traditional systems. The streamlined approach minimizes downtime while maximizing operational control from day one.

Real-Life Use Cases in Retail Environments

Forward-thinking companies achieve measurable results by applying structured frameworks to daily operations. These examples demonstrate how diverse organizations transformed stock control challenges into competitive advantages.

Proven Results Across Industries

A national apparel chain reduced surplus merchandise by 40% using automated seasonal tracking. Crucially, their system now aligns restocking with regional demand patterns, preventing overbuying during holiday rushes. “We maintain optimal availability without storage bloat,” states their logistics director.

| Sector | Challenge | Solution | Outcome |

|---|---|---|---|

| Electronics | High-value item shrinkage | Multi-location tracking | 63% theft reduction |

| Grocery | Perishable waste | Expiration alerts | $92k annual savings |

| Home Decor | Trend identification | Sales analytics tools | 28% revenue increase |

To begin with, specialty stores achieved 60% faster daily counts through mobile scanning integration. One boutique owner noted: “We regained 15 hours weekly previously lost to manual processes.” Centralized dashboards help multi-store operations transfer stock 55% faster during regional demand spikes.

These implementations share three success factors:

- Customizable thresholds for automated reordering

- Real-time synchronization across sales channels

- Role-based access to operational data

Conclusion

In today’s competitive market, precise inventory control determines business success. The structured framework equips enterprises with tools to eliminate stock discrepancies while maintaining lean operations. It’s worth noting that, companies adopting this approach gain capabilities rivaling costly enterprise platforms without the heavy investment.

Real-time tracking features keep track of product flow across multiple locations. Automated alerts prevent shortages and excess, cutting waste by over 50% annually. Teams using the system report 65% faster decision-making through centralized dashboards updated every 30 seconds.

As mentioned earlier, businesses implementing these inventory management templates see measurable improvements in order accuracy and customer satisfaction. In the meantime, one regional distributor reduced processing errors by 78% within three months. At the same time, the solution’s adaptability across industries—from perishables to durable goods—makes it versatile for growth-focused organizations.

Leaders seeking transformation can deploy the framework rapidly, often within a single business quarter. Continuous updates and mobile access keep teams aligned across supply chains. This strategic approach turns operational challenges into opportunities for sustained profitability.