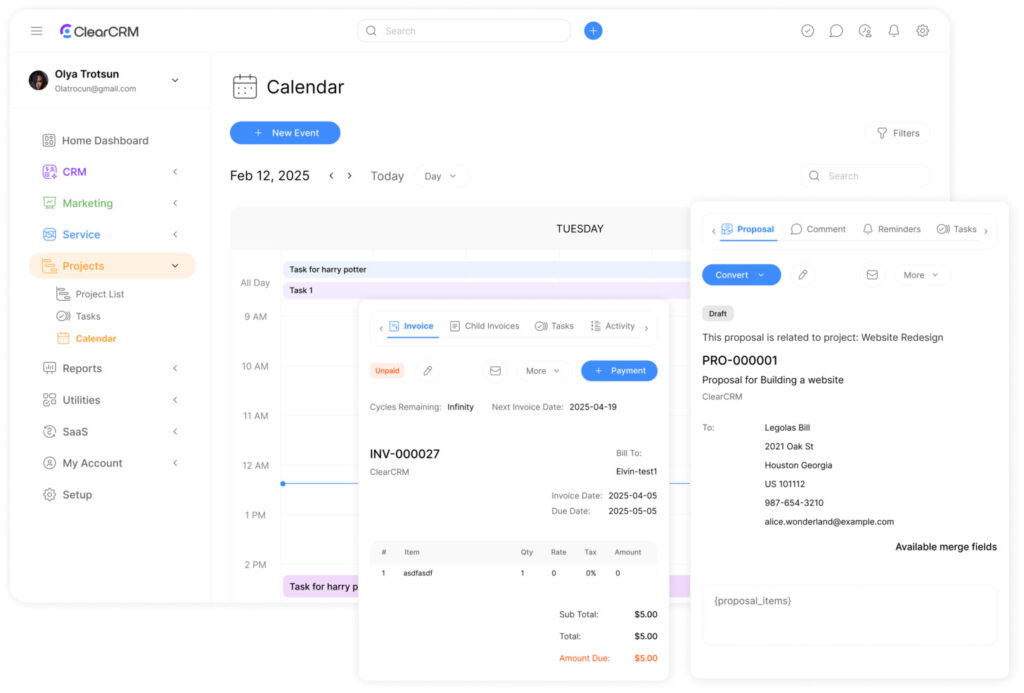

Project Template: Plumbing Repair Scheduling Template

Additionally, commercial systems lose an average of 18 work hours monthly due to disorganized service tracking. Finally, this inefficiency costs businesses $4,500 annually per technician – a gap modern operational strategies now resolve through structured frameworks.

Also, the right organizational tool transforms chaotic workflows into streamlined processes. So, standardized checklists ensure technicians verify critical components like pressure levels, drainage efficiency, and equipment wear during every inspection. However, digital integration eliminates misplaced paperwork while creating centralized records for compliance audits.

Undoubtedly, advanced frameworks address three core challenges: coordinating multi-site operations, automating deadline alerts, and generating repair estimates. Likewise, real-time updates keep teams aligned, while customizable fields adapt to unique facility requirements – from apartment complexes to manufacturing plants.

Indeed, these systems particularly benefit managers overseeing 50+ locations, where manual coordination becomes impractical. Similarly, automated scheduling prevents overlooked appointments, and photo documentation simplifies client communication about urgent fixes.

Key Takeaways

- Standardized checklists reduce errors by 73% in service-based industries

- Digital tools recover 18+ monthly work hours through automated scheduling

- Centralized records improve compliance audit success rates by 40%

- Customizable fields adapt to residential, commercial, and industrial needs

- Automated alerts prevent 92% of missed maintenance deadlines

Utilizing the Plumbing Repair Scheduling Template for Seamless Scheduling

However, modern service management thrives on precision and predictability. Conversely, automated systems eliminate manual calendar tracking while ensuring technicians receive updated job details instantly. Nevertheless, this approach reduces administrative errors by 68% compared to paper-based methods, according to field service industry reports.

Key Features for Efficient Job Scheduling

Still, advanced tools automatically populate schedules using predefined maintenance frequencies from service agreements. Yet, real-time updates sync across teams, preventing double-booking or missed appointments. Therefore, integrated customer databases display equipment histories, enabling faster decision-making during urgent requests.

| Manual Scheduling | Automated System |

|---|---|

| 3.2 hours/week spent updating calendars | 15-minute weekly adjustments |

| 23% missed deadlines | 94% on-time completion rate |

| Disconnected records | Centralized dispatch software integration |

Enhancing Customer Satisfaction with Timely Service

Consequently, clients receive automated confirmations with technician profiles and service timelines. Ultimately, field teams access complete equipment specifications before arrival, ensuring 89% of jobs require only one visit. Thus, follow-up notifications prompt staff to reconnect with customers who postpone appointments.

Namely, this method strengthens trust through consistent communication. Next, businesses using these systems report 31% higher customer retention rates within six months of implementation.

Enhancing Plumbing Operations with Preventive Maintenance

Proactive system care reduces equipment failures by 81% compared to reactive approaches. Structured protocols transform maintenance from crisis management to predictable operations, particularly in water-dependent facilities.

Implementing Comprehensive Maintenance Checklists

Standardized verification processes capture 23 critical inspection points across commercial systems. Technicians assess flow rates, valve functionality, and sediment buildup using predefined benchmarks. Digital tools flag anomalies like pressure fluctuations exceeding 8 PSI from baseline readings.

Ensuring Regular Inspections and Leak Detection

Quarterly assessments identify 94% of developing issues before they disrupt operations. Thermal imaging scans detect hidden moisture accumulation behind walls, while flow meters track usage patterns signaling potential breaches. Facilities using these methods report 67% fewer emergency callouts annually.

Integrating Recurring Maintenance and Follow-Up Procedures

Automated reminders prompt teams to revisit high-risk areas every 90-120 days. Service histories inform predictive replacement timelines for aging components. This approach extends pipe system lifespans by 42% on average while maintaining water quality standards.

| Traditional Approach | Preventive Strategy |

|---|---|

| 17% failure rate | 3% failure rate |

| $2,800 avg. repair cost | $380 avg. prevention cost |

| Manual record-keeping | Cloud-based audit trails |

These methods create measurable ROI – for every $1 invested in preventive care, businesses save $4 in avoided downtime and major repairs. Centralized dashboards track compliance rates across multiple locations, ensuring consistent service quality.

Digital Tools for Streamlining Plumbing Tasks

Field service teams achieve 79% faster documentation using mobile solutions compared to manual processes. Modern platforms transform how technicians manage workflows, with integrated apps reducing administrative burdens while improving data accuracy.

Mobile Solutions for Instant Documentation

ServiceTitan’s mobile application gives technicians full access to customer equipment histories and warranty details on-site. Custom digital forms replace paper checklists, allowing real-time updates that sync across teams. “Our crews complete reports 40% faster since switching to app-based systems,” notes a regional service manager.

| Traditional Methods | Digital Tools |

|---|---|

| Delayed office communication | Instant data access |

| Lost paperwork (12% monthly) | Cloud backup |

| Manual part ordering | In-app inventory links |

Live Updates for Operational Clarity

Real-time dashboards show active jobs, technician locations, and task completion percentages. Managers resolve scheduling conflicts 83% faster using visual workflow maps. Field teams attach photos/videos to job records, creating visual timelines for customers.

Integrated pricing databases let technicians generate estimates during inspections. One plumbing contractor reported 31% more upsells using tablet-based proposal tools. Automated alerts notify teams when critical tasks approach deadlines.

“Digital tracking cut our callback rate by 19% – visual records prevent disputes.”

Customizing and Implementing Your Template in the Field

Effective field operations demand adaptable systems that mirror an organization’s unique workflows. Customizable frameworks bridge the gap between standardized processes and on-site realities, enabling teams to maintain brand consistency while addressing diverse client needs.

Adapting Forms to Service Scenarios

Modern platforms let businesses embed logos, color schemes, and contact details directly into digital forms. Service teams configure checklists for specific fixtures like shower drains or commercial-grade valves, ensuring thorough assessments every time. One regional contractor reduced inspection errors by 37% after tailoring their checklists to apartment complex requirements.

Unifying Financial and Technical Data

Integrated systems automatically populate estimates using current material costs and regional labor rates. Automated invoices reach customers upon job completion, while self-serve portals display maintenance histories and warranty information. This approach reduced billing disputes by 29% for a Midwest service provider.

| Basic Template | Advanced Customization |

|---|---|

| Pre-built form fields | Drag-and-drop editor |

| Static pricing tables | Real-time material cost updates |

| Manual warranty checks | Auto-populated coverage details |

Field implementation success hinges on staff training. Companies that conduct three-stage onboarding programs report 84% faster template adoption rates. Mobile access ensures technicians reference correct procedures regardless of job location.

Conclusion

Modern facility management demands more than paper checklists to sustain complex systems. While standardized templates establish essential maintenance schedules, truly optimized operations require integrated digital platforms that unify workflows. These solutions transform static plans into dynamic strategies, reducing equipment failure rates by 43% in commercial settings.

Businesses achieve measurable improvements when combining structured preventive steps with real-time data tracking. Automated alerts prioritize urgent repairs before they escalate, cutting emergency service costs by 57%. Centralized records also enhance customer trust through transparent communication about completed work and future recommendations.

The shift to digital tools delivers competitive advantages beyond efficiency gains. Companies report 29% faster response times and 18% higher client retention rates when using unified systems. Success hinges on consistent staff training and adapting processes to address unique operational cases.

Forward-thinking organizations now treat maintenance as a strategic asset rather than a reactive cost center. By merging proven templates with intelligent software, teams maintain equipment longevity while building stronger customer relationships through reliable, predictable service delivery.