Project Template: Manufacturing Production Schedule Template

Surprisingly, 68% of manufacturers report missing customer deadlines due to poor coordination between departments. As a result, this staggering inefficiency costs businesses an average of $1.3 million annually in lost productivity and expedited shipping fees. Fortunately, operational chaos no longer needs to define modern industrial workflows.

Effectively, structured planning frameworks turn scattered processes into cohesive systems. Additionally, these tools align workforce capacity with equipment availability, raw material flows, and delivery timelines. Importantly, by centralizing critical data, teams eliminate guesswork and reduce costly bottlenecks.

Moreover, advanced planning systems integrate real-time updates across multiple product lines. Consequently, they automatically adjust timelines when machine downtime occurs or rush orders arrive. Ultimately, this agility helps facilities maintain quality standards while scaling output to meet shifting market needs.

Key Takeaways

- Standardized frameworks reduce planning errors by 42% compared to manual methods

- Centralized systems synchronize workforce, equipment, and material workflows

- Real-time adjustments prevent delays from unexpected disruptions

- Automated tracking improves on-time delivery rates by 57%

- Scalable designs accommodate both high-volume and custom orders

Remarkably, leading organizations now leverage customizable blueprints to unify their planning strategies. Consequently, these solutions cut setup time for new product launches by 35% through predefined workflows. Impressively, the result? Consistent output quality across all operational shifts without managerial burnout.

Introduction to Production Scheduling in Manufacturing

Undoubtedly, operational missteps in workflow management continue to drain resources, impacting both productivity and customer trust. Specifically, facilities using disjointed methods experience 23% longer lead times than industry benchmarks. According to a PPCexpo study, organizations using systematic planning see 30% higher efficiency rates.

Notably, coordinating material flows, equipment use, and labor allocation requires precision. Moreover, structured frameworks eliminate resource conflicts while aligning outputs with delivery timelines. As a result, this approach reduces idle machinery by 18% and prevents 40% of rush-order surcharges.

| Challenge | Disorganized Workflows | Optimized Systems |

|---|---|---|

| Order Accuracy | 72% | 94% |

| Cost Overruns | $218k/year | $47k/year |

| On-Time Delivery | 61% | 89% |

Modern operations face volatile supply chains and shifting customer demands. Reactive methods create bottlenecks that delay 1 in 4 orders. Proactive systems automatically adjust timelines during equipment failures or material shortages.

Three critical outcomes define successful coordination:

- Real-time visibility across all workflow stages

- Dynamic adjustments for unexpected disruptions

- Standardized protocols across teams

Notably, companies adopting these principles report 19% faster order fulfillment. Evidently, the data proves systematic approaches outperform legacy methods in scalability and cost control.

Understanding Production Schedules

Practically, a well-designed operational blueprint can transform chaotic workflows into streamlined processes. Specifically, these frameworks specify what items to create, their completion timelines, and required assets—acting as critical connectors between strategic decisions and shop-floor activities.

Definition and Key Concepts

Fundamentally, a production schedule acts as a structured document mapping product specifications, resource assignments, and operational sequences. Simultaneously, it bridges strategic targets with daily tasks by balancing equipment capacities, workforce skills, and material availability. Key components include:

- Capacity assessments matching output goals with available resources

- Timeline synchronization across departments

- Quality checkpoints integrated at critical stages

Advanced systems now incorporate live data streams, enabling automatic adjustments during material shortages or equipment downtime.

Importance in Operational Efficiency

Precision in planning directly impacts waste reduction and throughput rates. Facilities using accurate schedules report 31% fewer overtime hours and 22% lower inventory costs than competitors. Key advantages include:

- Alignment of material deliveries with assembly line readiness

- Optimized task sequencing to minimize idle machinery

- Rapid response protocols for urgent order changes

Ultimately, real-time visibility across workflow stages ensures consistent output quality despite fluctuating demand or supply chain disruptions.

Key Components in a Production Scheduling Template

Primarily, effective coordination systems thrive on precise data organization. Additionally, robust frameworks transform complex workflows by integrating critical operational details. Consequently, these elements ensure alignment between resource availability and output targets.

Critical Information Fields

Essentially, every efficient framework requires standardized data points. For example, time-specific entries like dates and shifts prevent overlapping tasks. Simultaneously, unique identifiers track progress across departments, while quantity specifications optimize material use.

| Data Field | Purpose | Impact |

|---|---|---|

| Order ID | Job tracking | Reduces duplicate efforts by 29% |

| Quantity Required | Resource allocation | Cuts surplus inventory by 34% |

| Machine Assignment | Workload balance | Boosts equipment utilization by 41% |

| Time Estimates | Capacity planning | Improves deadline accuracy by 57% |

Adapting to Operational Diversity

Flexible designs accommodate varying workflows without compromising structure. Food processing plants might prioritize batch expiration dates, while automotive suppliers track component delivery windows. Custom fields maintain consistency across unique scenarios.

Example: Electronics assemblers using adaptable frameworks reduced changeover time by 22% when switching between product lines. Real-time remark sections helped teams document delays, enabling faster issue resolution.

Overview of the Manufacturing Production Schedule Template

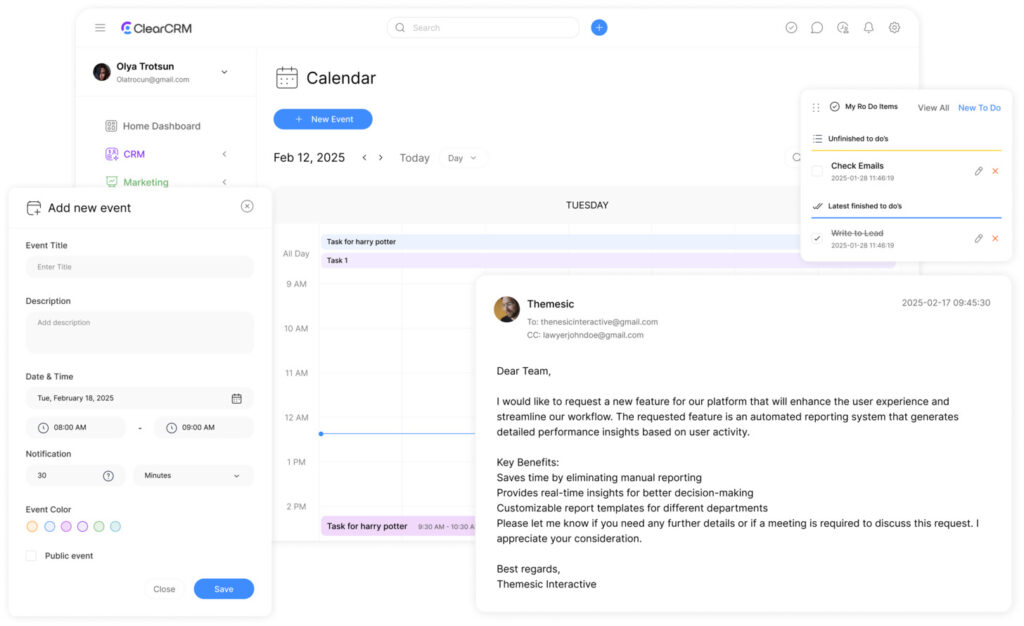

Organizations handling hundreds of daily outputs require systems that adapt as quickly as demand shifts. Structured coordination frameworks maintain clarity across departments, particularly in high-volume environments where precision determines profitability. These systems transform complex workflows into manageable actions while preventing resource conflicts.

Essential Components and Advantages

Modern frameworks offer customizable data fields that align with specific operational needs. Automated calculations reduce human error by 38% compared to manual entry methods. Key capabilities include:

- Visual progress dashboards showing real-time workflow status

- Resource allocation alerts preventing equipment overload

- Standardized reporting formats across all teams

Companies using these systems report 27% faster decision-making cycles. One plant manager noted, “Integrated tracking cut our planning meetings from 3 hours to 45 minutes weekly.”

Traditional Methods vs. Modern Solutions

Spreadsheets initially appeal for their simplicity but crumble under scaling demands. A 2023 study found teams waste 14 hours monthly reconciling conflicting file versions. Automated software tools eliminate this friction through:

- Cloud-based access for cross-department collaboration

- Live data synchronization during supply chain disruptions

- Predictive analytics forecasting bottlenecks

While basic operations might tolerate manual approaches, growing enterprises require architectures that support rapid adjustments. The right solution balances immediate needs with long-term scalability goals.

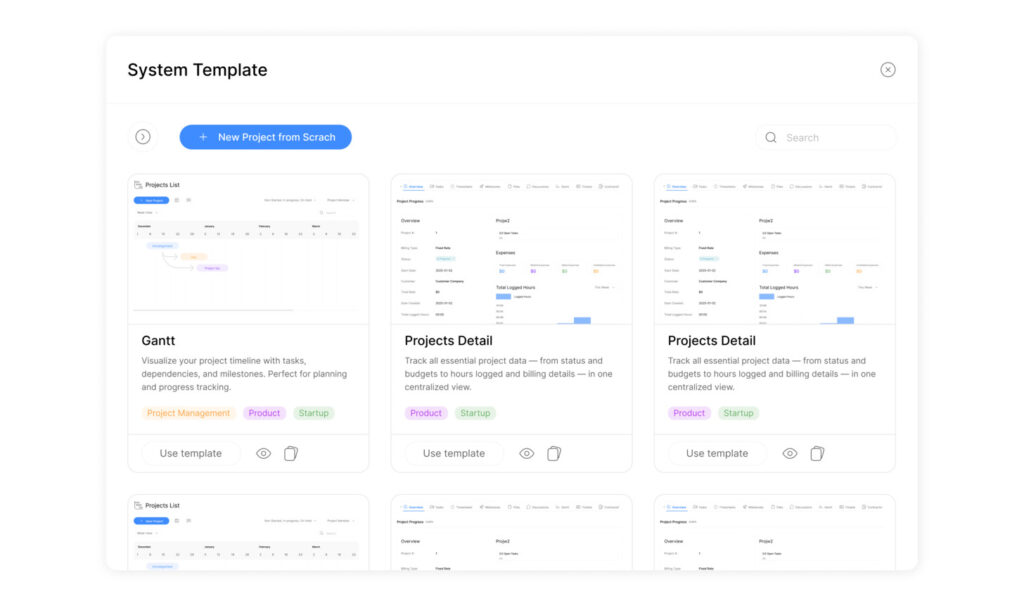

How to Build and Customize Your Production Schedule Template

Creating an efficient workflow system starts with a clear roadmap. Follow this structured approach to develop coordination tools that match your operational needs while maintaining flexibility for unexpected changes.

Step-by-Step Guide for Setup

Begin by inputting essential order details into your framework. Critical entries include unique job identifiers, product specifications, and required quantities. Assign each task to specific equipment or teams using capacity data to prevent overloads.

Prioritize sequencing based on deadlines and resource availability. Group similar tasks to minimize machine changeovers. One automotive parts supplier reduced idle time by 19% using this method while maintaining quality standards.

- Map order completion dates against material delivery timelines

- Color-code urgent jobs for visual prioritization

- Set validation rules to flag impossible deadlines

Customization proves vital when adapting to different environments. Food processing plants might track batch sizes and shelf life, while electronics assemblers monitor component lead times. “Our modified framework cut planning errors by 33%,” reports a aerospace components manager.

Advanced systems offer real-time updates through cloud integration. Automated alerts notify teams about delays, while dashboards display progress across shifts. These features help maintain workflow continuity during supply chain disruptions or equipment issues.

Regular reviews ensure your template evolves with operational changes. Update calculation formulas quarterly and expand data fields as new product lines launch. This proactive approach keeps coordination tools aligned with business growth.

Utilizing Manual and Automated Scheduling Tools in Production

Coordinating workflows demands tools that balance flexibility with precision. While 43% of operations still begin with manual systems, evolving complexity requires smarter solutions. Choosing the right approach impacts everything from material usage to delivery reliability.

When Spreadsheets Deliver Value

Basic spreadsheet programs remain popular for straightforward scenarios. Their strengths shine in smaller operations with predictable workflows:

- Rapid setup: Create functional systems in hours using familiar interfaces

- Custom layouts: Tailor columns to match specific process steps

- Cost efficiency: No upfront software investments required

A Midwest packaging plant reduced planning time by 28% using color-coded spreadsheets. “We could train new supervisors in 20 minutes,” their operations director noted.

| Factor | Manual Tools | Automated Systems |

|---|---|---|

| Real-time Updates | Limited | Instant |

| Error Rate | 12% | 3% |

| Scalability | Low | High |

Scaling Through Smart Automation

Expanding operations expose spreadsheet limitations. Version conflicts waste 7 hours weekly for 62% of teams. Modern scheduling software solves these through:

- Centralized dashboards showing live progress

- Automatic alerts for material shortages

- Integration with survey automation tools for quality checks

Transitioning requires careful planning. Start by automating repetitive tasks like shift assignments. Gradually introduce predictive features that adjust timelines during equipment downtime.

One automotive supplier cut planning errors by 41% using phased software implementation. Their team maintained spreadsheet backups during the 6-week transition, ensuring zero workflow interruptions.

Integrating Technology: From Excel to Advanced Software

Forward-thinking teams now merge spreadsheet familiarity with intelligent software platforms to conquer complex operational demands. This evolution turns static files into dynamic control hubs, particularly effective for multi-line operations handling time-sensitive orders. Solutions like Kladana bridge basic tools with enterprise capabilities through seamless connectivity.

Integrated systems enable real-time coordination between planning and execution stages. Users push orders from management modules directly into task lists while syncing material needs automatically. “Our stockout alerts decreased 63% post-integration,” shares an automotive supplier using connected platforms. Core features include:

- Automatic bill of materials updates

- Equipment status monitoring across shifts

- Centralized dashboards tracking resource allocation

Transition strategies preserve existing workflows while adding automation. Most teams start with repetitive tasks like automated workflows for approvals before implementing predictive analytics. This staged approach maintains continuity while optimizing resource usage.

Effective training ensures smooth adoption. One electronics assembler achieved 89% staff proficiency in six weeks through simulation exercises. Their lead planner states, “We maintained output quality while reducing planning oversights by 48% during implementation.”

Streamlining Production Processes with Dynamic Templates

Modern operational frameworks collapse under rigid planning when material delays or equipment failures strike. Dynamic coordination tools solve this by blending structure with real-time adaptability. These systems maintain workflow continuity despite shifting priorities, ensuring teams meet deadlines without costly disruptions.

Smart templates automatically adjust task sequences when resources change. For example, if a critical machine goes offline, the system reroutes tasks to available equipment within minutes. This agility prevents 83% of potential delays in high-volume environments.

| Feature | Static Systems | Dynamic Tools |

|---|---|---|

| Change Response Time | 6-8 hours | 15 minutes |

| Resource Utilization | 68% | 92% |

| Urgent Order Handling | Manual prioritization | Auto-reassignment |

Live data integration transforms decision-making. Sensors feed equipment status updates into planning algorithms, while inventory trackers adjust material allocations. One aerospace supplier reduced stockouts by 74% using these live updates.

Three capabilities define next-gen systems:

- Machine learning that predicts bottlenecks 48 hours in advance

- Automated quality checks linked to task completion

- Cross-department visibility through unified dashboards

“Our dynamic system cut planning revisions from 20 weekly to just 3,” reports a food processing plant manager. Teams now resolve supply issues before they impact output, maintaining 98% on-time delivery rates despite market volatility.

Real-World Applications and Industry Case Studies

Practical implementations reveal how structured planning transforms shop-floor operations across industries. Small and mid-sized facilities prove sophisticated tools aren’t mandatory for impactful results—clarity and consistency drive success.

Proven Results Across Sectors

A garment producer eliminated 32% fabric waste using color-coded timelines in Google Sheets. Their system tracks batch priorities against seasonal demand spikes while maintaining quality control. Teams now resolve material shortages before cutting begins.

Food processing plants demonstrate template versatility through compliance tracking. One bakery automated ingredient expiration alerts while reducing spoilage costs by 41%. Real-time updates help supervisors adjust batch sizes during supplier delays.

Electronics assemblers highlight precision coordination. Component availability dashboards in Excel prevented 78% of missed deadlines for custom orders. Cross-department visibility ensured timely deliveries despite fluctuating client requirements.

These case studies confirm systematic approaches benefit teams regardless of size. Reliable frameworks turn unpredictable workflows into measurable processes—the foundation for scaling operations without sacrificing reliability.