Project Template: Construction Project Timeline Template

Additionally, nearly 70% of large-scale builds face delays due to poor planning, yet teams using structured schedule templates complete work 35% faster. Finally, this gap highlights a critical truth: organized frameworks aren’t optional—they’re the backbone of success.

Also, modern construction schedule templates transform chaotic workflows into clear roadmaps. So, they map every phase, from permits to inspections, while balancing labor, materials, and deadlines. However, tools like Gantt charts simplify tracking, letting teams spot bottlenecks before they escalate.

Similarly, these adaptable frameworks cut administrative work by half for many firms. Likewise, instead of starting from scratch, managers customize pre-built structures to fit residential, commercial, or infrastructure needs. Indeed, automated alerts keep stakeholders aligned, reducing miscommunication risks.

Key Takeaways

- Pre-designed templates reduce planning time and improve deadline accuracy

- Visual tools like Gantt charts enhance progress tracking across teams

- Customizable frameworks adapt to projects of any size or complexity

- Integrated milestone markers help prevent costly delays

- Centralized resource allocation streamlines budget management

Overview of Construction Scheduling and Project Timelines

Similarly, teams that master timeline visualization reduce rework by 40% on average. Clearly, this approach transforms fragmented tasks into cohesive action plans, ensuring all phases align with client expectations and regulatory standards.

Blueprints for Success

Undoubtedly, a detailed schedule acts as the nervous system of any build. However, it maps labor shifts, material deliveries, and equipment usage while flagging permit expiration dates. Conversely, one project manager notes: “When everyone sees how their tasks fit into the bigger picture, delays become exceptions rather than norms.”

Clarity Through Visual Tools

Nevertheless, interactive charts highlight task overlaps and resource gaps in real time. For example:

- Color-coded phases show progress against deadlines

- Drag-and-drop interfaces adjust timelines during weather disruptions

- Automated alerts notify teams about approaching milestones

Still, these systems create shared understanding across architects, contractors, and inspectors. Yet, by centralizing updates, firms maintain momentum even when supply chains shift unexpectedly.

Essential Elements of a Construction Project Timeline

Therefore, effective build schedules separate successful outcomes from costly overruns. Consequently, at their core, they combine granular task organization with strategic progress markers. Ultimately, three components prove non-negotiable: clear work divisions, measurable checkpoints, and intelligent resource alignment.

Task Breakdown, Milestones, and Deadlines

Thus, work segmentation transforms complex builds into achievable daily goals. Namely, teams divide site activities into coded phases like foundation prep or mechanical installations. Next, one contractor explains: “When crews see their exact responsibilities, productivity jumps 25% overnight.”

Importantly, critical dates act as progress anchors. Overall, pouring concrete slabs or passing electrical inspections become celebrated wins that maintain momentum. Crucially, automated alerts remind teams when key dates approach, preventing oversights.

Managing Dependencies and Resource Assignments

Then, interconnected tasks demand careful sequencing. Afterward, drywall installations can’t start before framing passes inspections. Subsequently, modern tools visualize these relationships using:

- Color-coded dependency chains

- Drag-and-drop adjustment features

- Real-time conflict notifications

Smart resource allocation matches workers and materials to scheduled phases. Equipment arrives precisely when needed, avoiding storage fees or idle crews. This precision cuts waste while keeping budgets intact.

Benefits of Using a Gantt Chart for Construction Projects

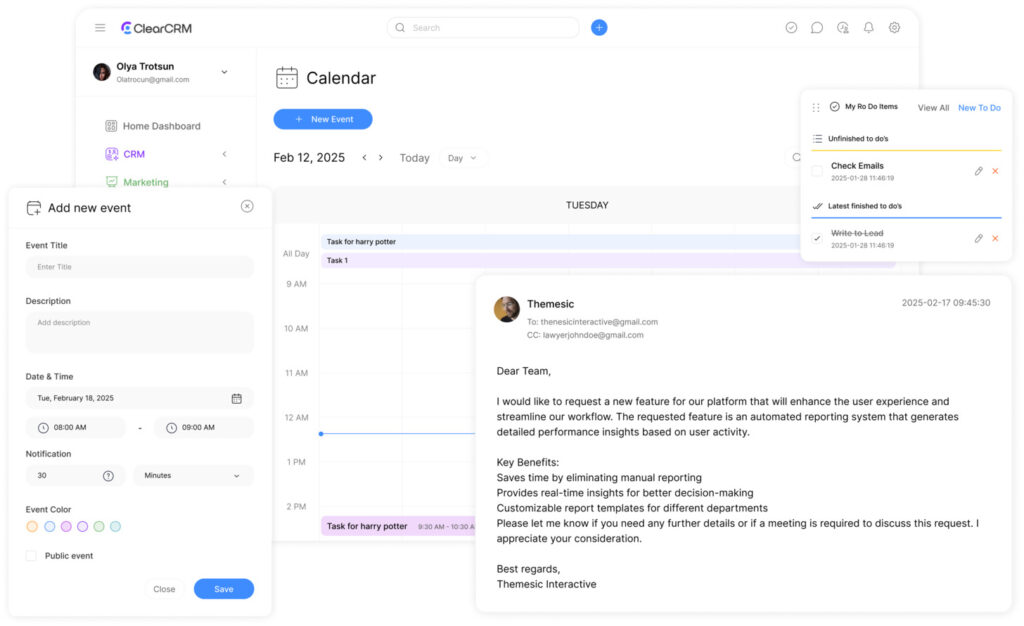

Gantt charts bridge the gap between planning and execution in high-stakes builds. These tools turn abstract timelines into actionable visual workflows, creating alignment across teams. When schedules shift—as they often do—the right framework keeps projects moving forward.

Why Gantt Charts Make Scheduling Simpler

Visual timelines reveal task connections that spreadsheets often hide. Managers see how electrical work depends on completed framing or why roofing can’t start before inspections. A Gantt chart maker simplifies adjustments: drag tasks to new dates, and dependencies auto-update.

One site supervisor notes: “Color-coded bars show who’s responsible for what—no more confusion about next steps.” This clarity reduces meetings by 30% in some cases, as teams reference a single source of truth.

Real-Time Progress and Efficiency Tracking

Live updates transform guesswork into precision. Green bars stretching across the chart indicate tasks ahead of schedule. Red zones trigger instant alerts, letting crews address delays before they snowball.

Efficiency metrics highlight patterns over time. If concrete pours consistently take 15% longer than planned, managers adjust future schedules. These insights help teams:

- Allocate workers where bottlenecks occur

- Reorder materials based on actual usage rates

- Balance equipment sharing between sites

By making data visible, Gantt charts turn reactive firefighting into proactive strategy. Stakeholders see progress at a glance, fostering trust and accountability.

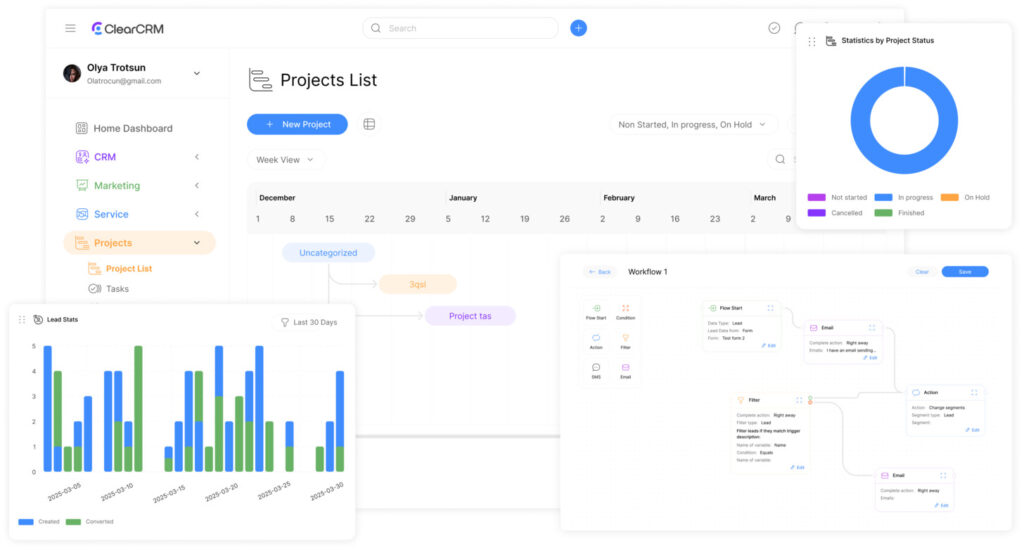

Construction Project Timeline Template: Enhancing Project Management

Efficient planning tools reshape how teams approach complex builds. Modern digital frameworks centralize scheduling processes, enabling instant updates across dispersed crews. A field supervisor observes: “Pre-built frameworks cut our planning meetings from weekly to monthly—they’re that intuitive.”

Core Components Driving Team Success

These systems integrate three critical elements:

- Drag-and-drop interfaces for rapid adjustments

- Centralized communication channels for subcontractors

- Automated progress tracking against benchmarks

Resource alignment becomes effortless when material orders sync with phase deadlines. Teams report 28% fewer supply chain disruptions using these methods. Real-time dashboards show equipment utilization rates, preventing costly idle time.

| Feature | Traditional Planning | Template Approach |

|---|---|---|

| Setup Time | 12+ hours | Under 45 minutes |

| Stakeholder Access | Email updates | Live mobile access |

| Change Implementation | 2-3 days | Instant sync |

| Error Frequency | 18% of projects | Below 4% |

Advanced formulas calculate labor needs based on square footage or project type. This precision helps managers allocate workers before shortages occur. One commercial developer notes: “We’ve reduced overtime costs by 37% since adopting these tools.”

Standardized documentation ensures compliance across multiple sites. New hires grasp workflows faster through visual task maps, shortening onboarding by 40%. These frameworks turn chaotic processes into repeatable success patterns.

Step-by-Step Guide to Creating Your Construction Schedule

Crafting an effective schedule begins with meticulous task mapping—a process that prevents 58% of common workflow errors according to industry studies. Teams using systematic approaches complete critical phases 22% faster than those relying on ad-hoc methods.

Listing Tasks and Setting Milestones

Start by decomposing deliverables using a work breakdown structure. One superintendent notes: “Detailed activity lists cut confusion—crews know exactly what’s needed each morning.” Collaborate with trade experts to sequence tasks logically, from excavation to finishing touches.

- Assign duration estimates using historical data

- Mark approval dates and inspection targets as progress markers

- Link dependent activities to maintain workflow integrity

Phases of Work: From Planning to Completion

Every build flows through three distinct stages. Preconstruction establishes foundations through design approvals and material sourcing. Physical execution follows, demanding precise coordination between crews and suppliers. Finalization ensures client satisfaction through rigorous quality checks.

| Stage | Key Activities | Duration Range |

|---|---|---|

| Preconstruction | Permit acquisition, subcontractor selection | 2-8 weeks |

| Execution | Foundation work, mechanical installations | 12-36 weeks |

| Closeout | Inspections, client training | 1-3 weeks |

Digital tools automate 73% of scheduling updates, letting teams focus on problem-solving. Regular reviews catch deviations early—adjust resource allocations before delays impact deadlines.

Optimizing Resources and Managing Team Collaboration

Coordinating specialized trades and equipment across multiple sites remains a top challenge for 83% of build managers. Modern solutions tackle this through intelligent frameworks that sync schedules, labor, and materials. Tools like centralized work platforms eliminate guesswork by showing real-time updates across teams.

Effective Strategies for Team and Subcontractor Coordination

Real-time dashboards prevent conflicts by displaying overlapping tasks. One site lead shares: “Mobile access lets electricians see plumbing progress before they arrive—no more wasted trips.” Subcontractors receive automated alerts when prerequisite work finishes, ensuring timely starts.

Key tactics include:

- Color-coded calendars showing trade availability

- Centralized document hubs for updated blueprints

- Daily progress snapshots sent to all stakeholders

Resource Management Best Practices

Heat maps reveal overbooked crews, allowing quick reassignments. Teams balance skilled workers across phases using predictive algorithms. A superintendent notes: “We reduced crane rental costs 19% by tracking equipment usage hourly.”

Essential practices:

- Match material deliveries to installation dates

- Reserve backup vendors for high-demand items

- Update labor pools based on certification expirations

Leveraging Free Construction Schedule Templates and Tools

Accessible scheduling tools empower teams to bypass costly software investments while maintaining precision. Free frameworks provide adaptable solutions that scale from small renovations to multi-phase developments, with platforms like Smartsheet and BuildBook offering specialized starting points.

Spreadsheet Solutions vs Cloud-Based Platforms

Excel-based systems appeal to teams needing offline access and formula-driven calculations. A residential contractor shares: “Dropdown menus let us quickly assign trades without retyping crew names.” These files work well for:

- Single-location developments under 6 months

- Budgets requiring strict formula controls

- Branding customization through color schemes

Online Gantt platforms like TeamGantt outperform spreadsheets for complex builds. Real-time updates keep subcontractors aligned across time zones. Features include:

- Automatic conflict detection during rescheduling

- Comment threads attached to specific tasks

- Mobile approvals for change orders

Tailoring Pre-Built Frameworks

Effective customization begins with identifying repetitive workflows. BuildBook’s templates let crews add:

- Specialty inspection checklists

- Custom material lead times

- Trade-specific safety protocols

One project lead notes: “We saved 14 hours weekly by modifying GanttPro’s base template with our electrical testing phases.” Most platforms allow exporting adjusted frameworks for reuse, creating institutional knowledge over time.

Tips for Integrating Budget and Materials Planning

Synchronizing cash flow with material availability prevents 45% of common financial bottlenecks in builds. Teams that align spending patterns with workflow demands maintain tighter control over margins while meeting deadlines. This fusion of fiscal oversight and logistical precision separates thriving developments from those plagued by delays.

Merging Fiscal Realities with Workflow Needs

Real-time tracking systems bridge accounting and operations. One financial controller notes: “When purchase orders sync with installation dates, we cut storage fees by 33% overnight.” Modern tools map material deliveries against phase budgets, creating automatic alerts when costs approach limits.

Key integration strategies include:

- Linking supplier invoices to task completion percentages

- Adjusting labor allocations based on weekly budget burn rates

- Using historical data to forecast material price fluctuations

| Challenge | Traditional Approach | Integrated Solution |

|---|---|---|

| Material Surpluses | 15% over-purchasing | JIT deliveries |

| Payment Delays | 45-day approval cycles | Automated milestone billing |

| Cost Overruns | Monthly budget reviews | Daily expense alerts |

Strategic supplier partnerships further stabilize workflows. Teams negotiate bulk pricing while securing backup vendors for critical items. This dual approach keeps installations moving even during supply chain disruptions.

Digital dashboards make sure all stakeholders see updated cost projections. When steel prices spike unexpectedly, managers instantly recalculate phase budgets without derailing progress. This agility turns potential crises into manageable adjustments.

Common Construction Scheduling Challenges and How to Overcome Them

Unpredictable site conditions test even the most detailed plans, but adaptable strategies keep builds on track. Proactive teams address disruptions through structured workflows and real-time communication tools.

Mitigating Delays from Weather and Supply Issues

Seasonal planning minimizes weather risks. Teams implement flexible scheduling by grouping indoor tasks during rainy months. One contractor notes: “We reserve 10% of our timeline for weather buffers—it’s saved three projects this year.”

Supply chain gaps require backup solutions. Partnering with alternate vendors ensures critical materials arrive on time. Digital dashboards track shipments, triggering alerts if delays exceed 48 hours.

Streamlining Adjustments When Timelines Change

Dynamic tools auto-update dependent tasks during shifts. When foundation work extends by two days, electrical installations reschedule automatically. This prevents cascading delays across trades.

Centralized platforms notify subcontractors instantly through mobile alerts. Change orders attach directly to revised schedules, maintaining accountability. Real-time visibility reduces miscommunication, keeping stakeholders aligned despite unexpected pivots.