The Ultimate Guide to Resource Capacity Planning

Businesses today face a critical challenge: aligning their workforce, equipment, and budgets with ever-changing customer needs. When organizations struggle to balance supply and demand, they risk missed deadlines, strained client relationships, and eroded profits. Effective capacity planning provides the framework to turn these challenges into opportunities, ensuring teams operate at peak performance without overextending resources.

A 2023 industry report reveals that 14% of companies struggle with workload management, while 13% face inefficient processes. These gaps highlight why modern enterprises need strategies that go beyond spreadsheets and guesswork. By analyzing current operations and forecasting future needs, leaders can make data-driven decisions about staffing, equipment use, and growth investments.

Forward-thinking organizations now leverage real-time analytics and predictive tools to optimize their resource capacity. This strategy identifies bottlenecks before they disrupt workflows, enabling teams to reallocate tasks or adjust timelines in advance. Companies adopting these methods report up to 10% margin improvements through smarter allocation of their assets.

This guide breaks down the capacity planning process into actionable steps, from assessing current capabilities to implementing scalable solutions. Decision-makers will learn how to balance short-term demands with long-term objectives while maintaining service quality and operational agility.

Key Takeaways

- Balancing workforce and equipment with demand prevents costly inefficiencies

- Data-driven strategies outperform traditional planning methods

- Real-time analytics help anticipate and resolve bottlenecks

- Optimized resource allocation boosts profit margins significantly

- Scalable systems adapt to both current needs and future growth

Introduction to Capacity Planning

Modern enterprises navigate tight deadlines and shifting priorities daily. To stay competitive, they need systems that balance workloads with available assets. This is where structured resource allocation becomes critical.

What It Means and Why It Matters

Resource capacity planning bridges the gap between team capabilities and project requirements. It evaluates staff skills, equipment availability, and budgets to match operational needs. Key metrics like utilization rates spotlight inefficiencies, while demand forecasting predicts upcoming challenges.

Consider a software team juggling multiple client deadlines. Without clear visibility into developer bandwidth, managers might overcommit – causing burnout or missed targets. Strategic analysis prevents these pitfalls by aligning workloads with realistic timelines.

“The difference between chaos and control often lies in anticipating needs before they become emergencies.”

Driving Growth Through Insight

Forward-thinking companies use these methods to answer pressing questions: Can we take on new clients? Do we need specialized hires? Where are bottlenecks forming? By analyzing trends and growth projections, leaders make informed choices about hiring, training, and tech investments.

For example, a logistics firm might discover its warehouse staff can’t handle holiday season volumes. Proactive adjustments – like temporary hires or automated sorting tools – prevent service breakdowns. Such decisions directly impact customer satisfaction and profit margins.

Effective strategies don’t just solve today’s problems. They create adaptable frameworks that scale with market shifts, ensuring businesses thrive in unpredictable environments.

The Fundamentals of Resource Capacity Planning

The cornerstone of operational efficiency lies in matching available resources to market demands. Companies that master this alignment reduce waste, improve service quality, and maintain competitive agility. This process requires systematic evaluation of workforce skills, equipment availability, and financial constraints against evolving customer expectations.

Aligning Resources with Business Demand

Resource capacity planning bridges daily operations with long-term goals. It answers critical questions: Do teams have the right tools? Are skill gaps limiting growth? How do seasonal shifts impact workloads? For example, a marketing agency might use resource tracking systems to ensure designers aren’t overbooked during peak campaign seasons.

“Alignment isn’t about having more resources—it’s about deploying smarter combinations of what you already own.”

| Tactical Approach | Strategic Approach |

|---|---|

| Focuses on immediate project needs | Optimizes enterprise-wide assets |

| Adjusts team assignments weekly | Forecasts hiring needs 6-12 months ahead |

| Uses real-time utilization data | Analyzes market trend correlations |

Effective resource planning balances quantitative metrics like utilization rates with qualitative factors like employee expertise. A logistics company might track warehouse staff productivity while also assessing cross-training opportunities to handle supply-demand fluctuations.

Three elements define success in this field:

- Baseline measurements of current capabilities

- Continuous monitoring of industry shifts

- Scalable frameworks that grow with the business

Types of Capacity Planning Strategies

Organizations achieve operational excellence by selecting frameworks that align with their risk profile and market dynamics. Five core methods help teams optimize asset deployment while maintaining service quality.

Proactive vs Reactive Models

The lead strategy acts as an offensive play, building surplus resources before demand spikes. Ice cream producers exemplify this approach – ramping up freezer space and seasonal staff before summer hits. This method requires precise forecasting tools to justify early investments.

In contrast, the lag strategy responds to confirmed demand signals. While cost-efficient, this model risks client dissatisfaction during sudden surges. Logistics companies often face this challenge when holiday shipments overwhelm existing fleets.

“Balancing ambition with pragmatism separates thriving enterprises from struggling operations.”

| Strategy | Approach | Best For | Risk Level |

|---|---|---|---|

| Lead | Preemptive scaling | Predictable markets | High upfront costs |

| Lag | Demand-driven growth | Budget-conscious firms | Service delays |

| Match | Incremental adjustments | Volatile industries | Monitoring complexity |

Flexible and Blended Solutions

Adjustment tactics help teams handle temporary spikes without long-term commitments. Marketing agencies frequently use freelancers during product launches, maintaining quality without fixed overhead. This approach works best when paired with reliable talent networks.

Hybrid models combine multiple methods for tailored solutions. A retail chain might use lead tactics for holiday inventory while applying match principles to staffing. Successful blends require:

- Real-time performance dashboards

- Cross-departmental coordination

- Scenario planning workshops

Choosing the right mix depends on financial flexibility, market volatility, and growth targets. Most enterprises evolve their approach as they gather operational data and customer feedback.

Developing a Comprehensive Capacity Planning Process

Building sustainable operational frameworks requires systematic evaluation of assets against evolving market needs. A robust capacity planning process transforms disjointed efforts into coordinated action, aligning teams across multiple timelines.

Cross-functional collaboration drives success. Operations leaders partner with finance and HR to map skill gaps and budget constraints. This alignment ensures resource decisions support quarterly targets and five-year growth plans equally.

“The best systems balance precision with adaptability – they’re built for today’s fires and tomorrow’s opportunities.”

Three phases define effective execution:

- Gap analysis: Teams identify discrepancies between current capabilities and projected demand

- Scenario modeling: Stress-test assumptions against market shifts or supply chain disruptions

- Adjustment protocols: Establish triggers for scaling teams or reallocating budgets

| Time Horizon | Focus Area | Key Metrics |

|---|---|---|

| Daily | Workforce utilization | Task completion rates |

| Quarterly | Technology investments | ROI projections |

| Yearly | Market expansion | Competitor benchmarks |

Advanced analytics tools elevate traditional planning processes. Real-time dashboards track equipment usage patterns, while predictive models simulate staffing needs for new product launches. These insights help leaders allocate resources where they generate maximum impact.

Successful frameworks document decision criteria and escalation paths. Clear governance structures prevent bottlenecks when adjusting to unexpected challenges – whether scaling up for a major contract or pivoting during economic downturns.

Integrating Capacity Planning into Project Management

Successful project delivery hinges on synchronizing team capabilities with evolving priorities. When project management strategies incorporate real-time resource insights, organizations reduce delays and improve stakeholder trust.

Matching Talent to Timelines

Studies show 68% of project managers oversee 3+ initiatives simultaneously. Without visibility into staff workloads, teams risk burnout or missed milestones. Dynamic allocation tools help redistribute tasks based on shifting deadlines and employee expertise.

“The best projects aren’t managed – they’re resourced. Give teams what they need when they need it, and execution follows.”

Three principles drive effective integration:

- Real-time dashboards: Track team availability across active projects

- Skill-based assignments: Align tasks with employee strengths

- Adjustment protocols: Define triggers for resource shifts

Forward-thinking companies use these methods to cut project overruns by 19%. When marketing agencies adopted integrated systems, they reduced context-switching time by 27% through centralized task management.

Cross-department collaboration remains critical. Regular check-ins between project managers and operations teams ensure capacity forecasts match delivery expectations. This alignment prevents last-minute scrambles for specialized staff or equipment.

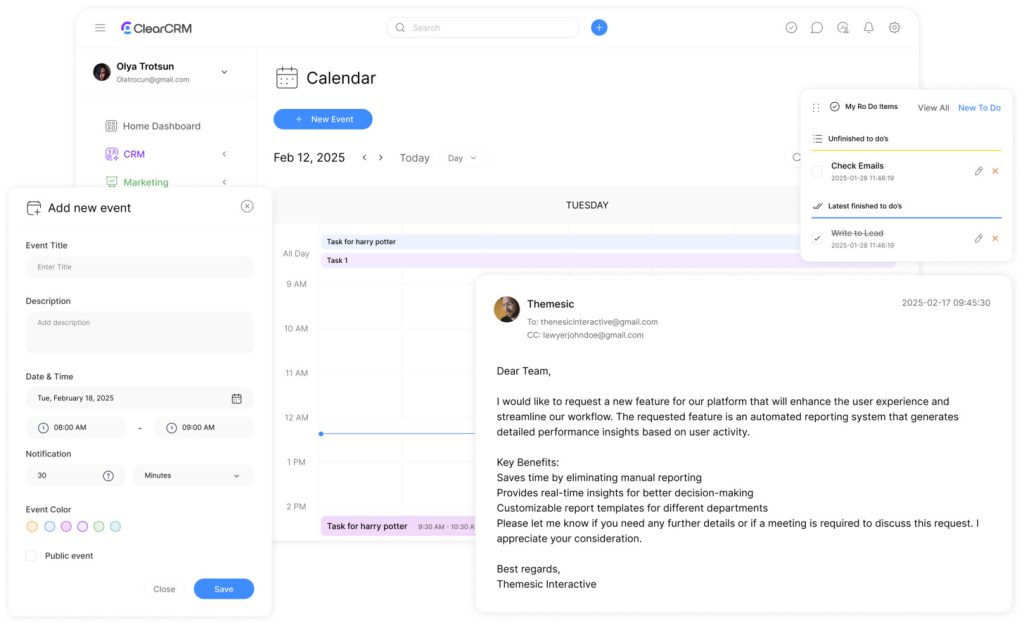

Utilizing Capacity Planning Software and Tools

Modern businesses require precision in aligning their workforce and assets with operational demands. Specialized solutions now automate complex calculations while surfacing critical insights through intuitive interfaces.

Benefits of Advanced Solutions

Capacity planning software replaces error-prone spreadsheets with automated workflows. Teams gain instant visibility into staff availability, project timelines, and budget constraints through unified dashboards. A 2024 Forrester study found companies using these tools reduced resource allocation errors by 43%.

“Advanced tools transform reactive guesswork into proactive strategy – they’re the difference between surviving and thriving.”

| Aspect | Manual Methods | Software Solutions |

|---|---|---|

| Data Accuracy | Prone to human error | Automated updates |

| Response Time | Days to adjust plans | Real-time changes |

| Scalability | Limited by spreadsheet size | Handles enterprise needs |

Leading planning tools integrate with financial systems to track performance hourly rather than monthly. This helps managers spot bottlenecks before they delay deliverables. Marketing agencies using these platforms report 22% faster project completion rates.

Key advantages include:

- Automated scenario modeling for demand spikes

- Skill-matching algorithms for optimal task assignments

- Collaboration features that sync teams across time zones

Investing in dedicated management software pays dividends through reduced overtime costs and improved client retention. Organizations achieve 18-month ROI averages by eliminating redundant administrative tasks.

Forecasting and Demand Analysis Techniques

Accurate predictions separate market leaders from reactive competitors. Organizations now combine historical data with market trends to anticipate client needs and align resource capacity. This approach transforms uncertainty into actionable strategies.

“Forecasting isn’t about crystal balls – it’s connecting data points to reveal tomorrow’s opportunities today.”

Demand analysis examines customer behavior patterns and seasonal shifts. Advanced algorithms process these inputs to predict supply demand imbalances before they disrupt workflows. Retailers use these models to optimize inventory levels before peak shopping seasons.

| Method | Focus | Impact |

|---|---|---|

| Workload Forecasting | Staff skill alignment | Reduces overtime costs by 18% |

| Scenario Planning | Risk mitigation | Cuts crisis response time by 41% |

| Predictive Modeling | Equipment utilization | Boosts asset ROI by 29% |

Three elements define successful planning capacity frameworks:

- Multi-source data integration from CRM and ERP systems

- Regular accuracy audits against real-world outcomes

- Collaborative reviews between finance and operations teams

These techniques enable proactive adjustments – like scaling cloud server space before product launches or reallocating budgets for emerging markets. Companies that master demand analysis report 23% faster adaptation to economic shifts compared to industry peers.

Creating a Resource Capacity Plan

Successful organizations structure their operations through layered frameworks that address immediate needs while fueling growth. This approach transforms fragmented decisions into coordinated strategies across multiple timelines.

Time Horizons That Drive Results

Short-term resource plans tackle daily challenges like staff scheduling and equipment availability. Teams use real-time dashboards to redistribute workloads during unexpected spikes, ensuring smooth service delivery. For example, hospitals adjust nurse rotations based on sudden patient influxes.

Mid-range strategies bridge operational firefighting with visionary goals. Marketing departments might allocate designers to Q4 campaigns while reserving budget for next year’s tech upgrades. This phase balances quarterly targets with annual expansion roadmaps.

Long-term capacity plans require bold investments in workforce development and infrastructure. Automotive manufacturers might train engineers in EV technology years before market shifts. These decisions align with five-year revenue projections and sustainability commitments.

Effective frameworks connect all three horizons through regular reviews. Retail chains analyze holiday sales data to refine inventory systems while planning new store openings. This coordination prevents disjointed decisions that undermine efficiency.

Leaders who master multi-layered resource capacity management build adaptable organizations. They turn unpredictable markets into opportunities through foresight and precise execution.