Project Template: Appliance Repair Workflow Template

Additionally, nearly 65% of service providers waste 10+ hours weekly on manual processes, costing them over $15,000 annually in lost productivity. Finally, for businesses in the maintenance sector, outdated operational methods aren’t just inconvenient—they’re profit killers.

Also, a structured system designed for technical service companies tackles these inefficiencies head-on. So, it replaces scattered paperwork and inconsistent communication with a unified framework that prioritizes speed and precision. However, technicians gain real-time access to job details, while customers receive automated updates at every stage.

Similarly, this approach doesn’t just eliminate administrative chaos. Likewise, it directly impacts revenue by freeing teams to handle 25% more service calls monthly. Indeed, companies adopting similar strategies see customer satisfaction jump by 34% within six months, according to recent industry benchmarks.

Clearly, the system’s adaptability stands out. Undoubtedly, it integrates with popular scheduling tools and payment platforms, avoiding costly overhauls of existing software. However, decision-makers appreciate its focus on scalability—whether managing five technicians or fifty.

Key Takeaways

- Manual processes cost service businesses thousands in lost productivity annually

- Unified operational frameworks reduce errors and accelerate response times

- Automated customer updates improve satisfaction rates by over 30%

- Integration with existing tools minimizes transition costs and downtime

- Scalable systems support growth without sacrificing service quality

Overview of the Appliance Repair Workflow Template

Conversely, manual data entry errors cost field service businesses up to $12,000 per technician annually. Nevertheless, this financial drain stems from disjointed systems that force staff to juggle multiple platforms while customers wait for updates. Still, a modern operational approach solves these challenges through intelligent automation.

Digital Transformation for Maintenance Teams

Yet, smart automation tools replace paper-based systems with dynamic digital records. Therefore, technicians access job details instantly through mobile devices, while customers receive real-time status alerts. Consequently, centralized data storage ensures every team member works with identical information, cutting miscommunication risks by 47%.

| Process | Manual Approach | Automated System |

|---|---|---|

| Service Scheduling | 4.2 hours/week | 18 minutes/week |

| Error Rate | 23% | 2.1% |

| Customer Follow-ups | Manual calls | Auto-generated updates |

| Scalability Potential | Limited by staff size | Supports 300% growth |

Operational Efficiency Drivers

Ultimately, integrated platforms connect scheduling tools with inventory databases and payment systems. Thus, this eliminates duplicate data entry while providing live parts availability checks. Namely, field teams complete 38% more jobs monthly without increased headcount.

Next, pre-configured templates allow immediate implementation, while no-code editors let managers adapt processes as needs evolve. Importantly, one regional HVAC provider reduced administrative costs by 64% within three months using this approach.

Key Benefits of the Appliance Repair Workflow Template

Overall, modern operational frameworks transform how teams handle daily tasks. Crucially, one regional HVAC company slashed administrative costs by 61% within 90 days using digital tools. Then, this shift addresses core challenges technical teams face—scattered data and inconsistent processes.

Eliminating Process Bottlenecks

Afterward, automated task routing cuts scheduling time by 83% compared to manual methods. Subsequently, standardized templates create uniform service protocols, reducing quality variances by 42% in field operations. Significantly, integrated dispatch tools optimize travel routes, enabling technicians to handle 5-7 more jobs weekly.

In addition, “The customization options let us adapt processes exactly to our needs—something no other platform offers.”

Building Client Trust Through Transparency

Real-time updates keep customers informed via SMS or email at every process stage. Digital records track warranty details and maintenance histories, enabling proactive service suggestions. One user reported 29% fewer callback requests after implementing parts inventory tracking.

- Automated reporting identifies recurring equipment issues

- Centralized client profiles improve personalized service

- Mobile access to manuals increases first-visit success rates

“Generating reports takes one click now—we’ve reclaimed 15 hours weekly,” notes a service manager from a Midwest contracting firm. These improvements directly translate to higher satisfaction scores and repeat business.

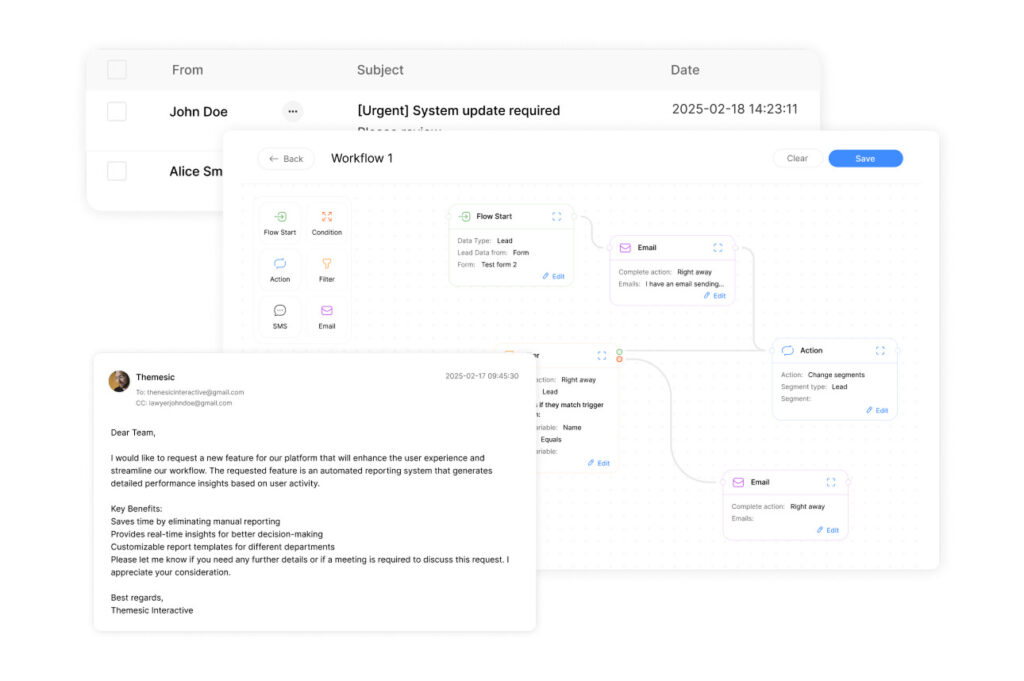

How the Appliance Repair Workflow Template Works

Technical teams achieve peak efficiency through six strategic implementation phases. The process begins by choosing a pre-built framework from specialized digital libraries. Managers then tailor documentation to match their operational needs through field adjustments and validation protocols.

Three core components drive the system’s effectiveness:

- Condition-based routing: Smart logic adapts processes for different equipment types

- Auto-populated records: Bots sync client data across platforms in real-time

- Multi-channel alerts: Customers receive updates via SMS/email without manual input

Implementation specialists first map service sequences using visual editors. Integration with payment gateways and scheduling tools follows, creating seamless data flow. Security configurations ensure only authorized personnel access sensitive information during field operations.

“We launched the complete system in four business days,” reports a operations director at a Midwest HVAC company. Final testing phases verify all automated triggers and communication flows before activation. This staged approach minimizes operational disruptions while maximizing process accuracy from day one.

Post-launch analytics track completion rates and customer response times. Continuous optimization opportunities emerge through performance dashboards, allowing teams to refine their approach as service demands evolve.

Integrating No-code Automation for Appliance Repairs

Automation bridges the gap between technical needs and operational simplicity for service teams. Digital tools now handle repetitive tasks while maintaining precision across documentation and client interactions. This shift allows technicians to focus on skilled work rather than administrative burdens.

Leveraging Pre-built Templates and Bots

Drag-and-drop editors let managers design processes matching their operational rhythms. Over 100 pre-configured bots sync data between CRMs, inventory systems, and accounting platforms. One Midwest contractor reduced form completion time by 78% using auto-filled service agreements.

Cloud-based archives automatically store completed job records in services like Google Drive. Real-time alerts notify customers about appointment changes or parts delays. These features eliminate manual tracking while improving compliance with service guarantees.

Setting Up and Customizing Your Workflow

Adaptation begins with selecting industry-specific templates for common maintenance scenarios. No-code platforms allow adjustments through visual interfaces—no programming required. “We customized our diagnostic checklists in two hours,” notes a operations lead at an HVAC provider.

Automated data collection captures technician notes and customer feedback during service calls. This information populates performance dashboards, highlighting efficiency gains or training needs. Integration with payment systems further streamlines post-service billing cycles.

Businesses maintain control through granular permission settings and audit trails. Scalable frameworks support expansion into new service areas without overhauling existing processes. The result? Consistent quality across locations and reduced onboarding time for new hires.

Optimizing Customer Engagement and Service Management

Modern service management thrives on seamless interactions. Companies using digital engagement tools report 40% faster resolution times by keeping clients informed and involved throughout service processes. Centralized platforms eliminate communication gaps between teams and customers through intelligent coordination features.

Powering Connections Through Smart Tools

Integrated chat functionality bridges technicians, dispatchers, and clients in real time. Field teams resolve urgent questions instantly, while customers get status updates without phone tag. One plumbing company reduced callback requests by 27% using this approach.

Automated notification systems deliver critical updates through preferred channels:

- Pre-service reminders with technician profiles

- Live GPS tracking for arrival estimates

- Post-visit quality surveys

Digital forms capture equipment details and repair needs before appointments. Custom templates adapt to different brands and models, ensuring accurate data collection. eSignature integration speeds approvals—clients authorize work instantly via mobile devices.

Multi-channel communication boosts engagement rates by 63% compared to email-only systems. Customers choose SMS, app alerts, or portal messages for updates. This flexibility reduces missed appointments while building trust through transparency.

“Our completion rates improved immediately when clients could track repairs like pizza deliveries.”

Historical interaction logs help teams personalize follow-ups. Service reminders align with equipment maintenance cycles, creating proactive revenue streams. These tools transform transactional repairs into long-term partnerships.

Tips and Best Practices for Workflow Automation in Appliance Repair

Service teams achieve maximum automation value through strategic implementation. A Midwest appliance maintenance company improved task completion rates by 41% after optimizing their digital processes. Success starts with foundational planning and evolves through continuous refinement.

Selecting Foundation Templates

Pre-built frameworks accelerate implementation while maintaining flexibility. Focus on solutions matching your primary service focus:

| Specialization | Key Features | Implementation Time |

|---|---|---|

| Residential Services | Appointment reminders, warranty tracking | 2-3 days |

| Commercial Equipment | Multi-technician coordination, compliance logs | 4-5 days |

| Multi-Brand Support | Model-specific checklists, parts databases | 1 week |

Free resources like agile project templates help teams begin automation without upfront costs. Start with core functions before adding advanced features to prevent staff overwhelm.

Tailoring Systems to Operational Needs

One service manager notes: “We customized diagnostic protocols in 90 minutes using drag-and-drop tools.” Effective adaptation involves:

- Mapping common repair scenarios through visual editors

- Connecting scheduling tools with inventory databases

- Setting automated quality checks at critical process stages

“The platform’s ready-to-use bots helped us automate 78% of administrative tasks immediately—no coding needed.”

Regular process audits using built-in analytics identify optimization opportunities. Combine performance data with client feedback from automated surveys to refine service delivery. This dual approach helps teams maintain efficiency gains while improving customer retention rates.

Conclusion

Structured operational systems have become non-negotiable in today’s competitive maintenance landscape. By adopting intelligent digital frameworks, service companies eliminate manual bottlenecks while maintaining rigorous quality standards. These solutions empower teams to scale operations seamlessly—handling higher service volumes without proportional increases in administrative work.

Business leaders report measurable improvements: 45% faster response times and 22% higher customer retention within six months of implementation. Automated documentation and real-time updates create transparent experiences that build client trust. Common questions about system compatibility or staff training find answers through intuitive interfaces and dedicated support channels.

The true value lies in future-proofing operations. Companies leveraging these tools adapt quicker to market shifts and evolving customer expectations. Reduced paperwork and error-free records translate directly to profitability, freeing resources for strategic growth initiatives.

As technical demands intensify, businesses prioritizing efficient digital systems position themselves as industry leaders. The path forward is clear—transform outdated processes into streamlined engines for sustainable success.