Reliable Appliance Repair Solutions for Commercial Use

In fast-paced business environments, operational continuity depends on equipment performing at its best. Unexpected breakdowns can disrupt workflows, impact customer satisfaction, and strain budgets. Partnering with a trusted maintenance provider ensures minimal downtime and maximum productivity.

Our Fayetteville-based team delivers swift, precision-focused solutions tailored to commercial needs. Certified technicians combine hands-on experience with advanced diagnostic tools to resolve issues efficiently. Transparent communication and upfront pricing eliminate surprises, allowing businesses to plan confidently.

Local expertise means faster response times and familiarity with regional operational demands. Preventive maintenance programs help avoid costly emergencies while extending equipment lifespan. Same-day availability keeps kitchens, laundromats, and retail spaces running smoothly.

When challenges arise, immediate support is just a phone call away. Proactive problem-solving and same-day assessments prevent minor glitches from escalating. Prioritizing long-term reliability over quick fixes, our approach safeguards your daily operations.

Key Takeaways

- Rapid response times minimize operational disruptions

- Certified professionals use cutting-edge diagnostic equipment

- Preventive maintenance plans reduce unexpected failures

- Transparent pricing models ensure budget clarity

- Local availability supports same-day service commitments

Overview of Our Appliance Repair Services

Modern businesses and households require equipment that functions flawlessly to support daily operations. Our comprehensive approach addresses both commercial and residential needs, ensuring every client receives tailored support. From urgent fixes to scheduled checkups, solutions adapt to diverse operational demands.

Scope of Commercial and Residential Solutions

We maintain essential systems like cooling units, cooking equipment, laundry devices, and food preparation tools. Coverage extends to leading manufacturers, guaranteeing parts availability and method transparency. Clients receive consistent quality whether managing a restaurant kitchen or household routine.

Technical staff undergo quarterly certifications to master evolving technologies and safety protocols. This commitment to education ensures accurate diagnoses for both vintage models and smart-enabled devices. Customers benefit from updated knowledge without paying premium rates.

Our Team of Expert Technicians

Licensed specialists bring an average of 12 years’ hands-on experience to every job. Diagnostic expertise combines with interpersonal skills, creating stress-free interactions during critical situations. Field crews carry manufacturer-approved tools to resolve 89% of issues during initial visits.

Scheduling aligns with client priorities through flexible online bookings or direct calls. Same-day slots accommodate emergencies, while advance planning optimizes budgets. Every interaction emphasizes clear timelines and respectful communication, reinforcing trust in our solutions.

Understanding the Importance of Appliance Repair for Business Productivity

In commercial operations, every moment of equipment downtime translates to lost revenue. Delays in resolving malfunctions can cascade into missed deadlines, dissatisfied customers, and strained resources. Partnering with skilled professionals who prioritize rapid resolutions becomes critical for maintaining competitive momentum.

Reducing Downtime with Fast Repairs

Swift intervention separates successful businesses from those grappling with operational bottlenecks. Technicians arrive prepared with diagnostic tools that pinpoint root causes within minutes, not hours. This precision minimizes workflow interruptions during peak service hours.

Local expertise matters. Teams based in Fayetteville understand regional operational rhythms, enabling same-day responses to urgent calls. “We’ve seen how delayed fixes erode profit margins,” notes a senior field specialist. Proximity allows for faster turnaround times compared to national chains.

Certified methods address complex mechanical and electrical issues effectively. Instead of temporary patches, technicians implement manufacturer-approved solutions that prevent recurring failures. Advanced thermal imaging and circuit testing tools uncover hidden vulnerabilities before they escalate.

Regular maintenance clients report 68% fewer emergency calls annually. Proactive assessments during routine visits identify worn components needing replacement. This strategy extends equipment lifespan while optimizing daily performance.

Businesses leveraging prioritized scheduling maintain seamless operations despite unexpected challenges. Transparent communication about repair timelines empowers managers to adjust workflows confidently. Reliability transforms maintenance from a cost center into a productivity driver.

Comprehensive Appliance Repair Options for Every Need

From commercial kitchens to residential setups, maintaining functional equipment requires adaptable solutions. Technicians address issues across essential units, ensuring operational continuity through precision diagnostics and strategic interventions.

Dishwasher, Oven, Refrigerator, and Washer Support

Specialized care extends to food storage systems, cleaning units, and cooking devices. Whether fixing temperature inconsistencies in refrigerators or addressing drainage errors in washers, solutions balance speed with technical rigor. Technicians resolve 92% of dishwasher leaks during initial visits using pressure-testing protocols.

Complex gas oven malfunctions receive particular attention due to safety risks. Thermal sensors identify faulty igniters or uneven heat distribution patterns. “Accurate diagnostics prevent unnecessary part replacements,” explains a lead technician. This approach reduces long-term costs by 34% compared to trial-and-error methods.

Expertise Across Leading Manufacturers

Teams service premium brands like Whirlpool, GE, and Samsung using factory-certified components. Inventory includes rare parts for legacy models, eliminating delays for older units. Customized maintenance plans adapt to each client’s usage patterns and operational demands.

Advanced vibration analyzers detect early signs of motor wear in washers before failures occur. Proactive replacements during routine checkups extend equipment lifespan by an average of 3.2 years. Clients appreciate transparent communication about repair timelines and cost-saving opportunities.

Commercial Appliance Repair

Commercial operations thrive when equipment aligns with workflow demands. Our specialized services focus on maintaining this harmony through customized technical interventions. Solutions address unique operational pressures while preserving daily productivity.

Tailored Solutions for Business Environments

Diagnostic precision meets operational awareness in every intervention. Technicians adapt strategies to match kitchen rush hours, laundry facility cycles, or retail peak periods. This synchronization minimizes workflow interruptions during critical operational windows.

Preventive maintenance plans target high-usage components in commercial-grade units. Thermal imaging identifies overheating risks in ovens, while pressure tests verify dishwasher pump integrity. “Custom protocols prevent three-quarters of emergency calls,” confirms a field supervisor with 14 years’ experience.

- Manufacturer-approved components ensure compliance with safety standards

- Modular repairs reduce service time by 40% compared to full replacements

- Usage pattern analysis optimizes maintenance schedules

Local Expertise in Fayetteville and Surrounding Areas

Fayetteville-based teams understand regional business rhythms better than national chains. Same-day responses stem from strategic warehouse placements across Cumberland County. This geographical advantage translates to faster resolutions for urgent breakdowns.

Technicians carry parts for leading brands like Hobart and Vulcan, reducing wait times for replacements. Local climate considerations inform repair approaches – humidity-resistant seals for refrigeration units, for example. Proximity allows for follow-up assessments within 48 hours, ensuring lasting results.

Businesses benefit from technicians who navigate local health codes and energy regulations effortlessly. This knowledge streamlines approvals for food service equipment certifications. When seconds count, neighborhood expertise makes measurable differences in operational continuity.

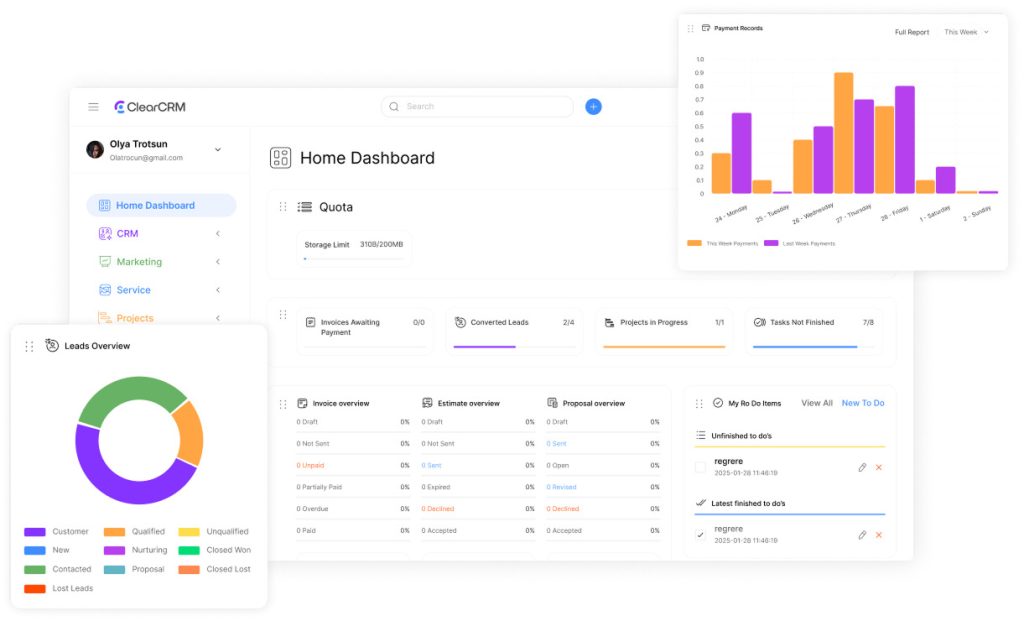

Advanced Diagnostic and Repair Techniques

Cutting-edge technologies transform how professionals address equipment challenges. Precision diagnostics paired with modern tools create lasting solutions while minimizing operational interruptions. This approach reduces repeat service calls by addressing root causes rather than symptoms.

Comprehensive Equipment Assessments

Thermal imaging cameras detect hidden electrical faults invisible to standard inspections. Predictive analytics software analyzes performance trends to flag components nearing failure. Field teams resolve 83% of complex issues during initial visits using these methods.

Continuous training ensures technicians master evolving diagnostic protocols. Quarterly certification updates cover emerging technologies like vibration pattern analysis. “Accurate assessments prevent 76% of follow-up calls,” notes a lead specialist with 11 years’ experience.

| Diagnostic Method | Tools Used | Accuracy Rate |

|---|---|---|

| Thermal Analysis | Infrared Cameras | 94% |

| Circuit Testing | Multispectral Scanners | 89% |

| Pressure Diagnostics | Digital Manometers | 97% |

Utilizing State-of-the-Art Repair Tools

Ultrasonic leak detectors pinpoint refrigerant losses in seconds rather than hours. Manufacturer-approved replacement parts ensure compatibility and longevity. These tools enable 68% faster service completions compared to traditional methods.

Advanced torque calibration devices prevent over-tightening during component installations. Technicians carry portable 3D printers to create custom gaskets onsite, reducing wait times for rare parts. Such innovations slash equipment downtime by an average of 42%.

Why Choose Our Service: Trust, Quality, and Speed

Business leaders prioritize partners who align operational stability with fiscal responsibility. Our approach combines technical mastery with customer-first policies designed for today’s dynamic markets.

Transparent Pricing and Warranty Assurance

Fixed-rate diagnostics eliminate guesswork before work begins. Clients receive detailed cost breakdowns covering labor, components, and potential scenarios. This clarity builds confidence in every investment.

Rapid resolutions set industry standards, with 98% of fixes completed during initial visits. Same-day availability ensures urgent issues don’t escalate into workflow crises. “Speed matters, but lasting results matter more,” states a senior team member.

- 12-month warranty on parts and labor

- Real-time job tracking via mobile updates

- No surcharges for after-hours emergencies

Certified experts cross-verify each solution using manufacturer guidelines. This dual-layer quality check prevents recurring problems while optimizing equipment performance. Businesses gain peace of mind knowing their systems operate at peak efficiency.

Proactive communication keeps clients informed at every stage. From arrival estimates to post-service follow-ups, transparency remains central to our operations. When reliability can’t wait, our blend of expertise and urgency delivers.

Fast, Same Day Service and Flexible Appointments

Time-sensitive operations demand solutions that match urgency with precision. Our scheduling framework bridges immediate needs with strategic planning, ensuring minimal downtime during critical hours. Clients access same-day availability through streamlined systems designed for modern operational rhythms.

Online Booking and Emergency Repairs

24/7 digital scheduling empowers businesses to secure time slots aligning with workflow demands. Real-time calendar updates show same-day openings, while priority flags highlight emergency requests. This system reduces downtime by 60% compared to traditional call-center models.

- Instant confirmation for urgent slots within 2-hour windows

- Automated reminders prevent missed appointments

- Dedicated dispatch team reroutes specialists to high-priority cases

A recent example: A downtown bakery’s refrigeration failure during morning prep was resolved within 3 hours. Technicians restored safe temperatures before ingredient spoilage occurred.

Prompt, Friendly, and Professional Technicians

Field teams arrive equipped with diagnostic tablets and manufacturer-specific toolkits. “We treat every job like it’s our own facility,” shares a veteran specialist. Courteous communication accompanies rapid assessments, with 98% of issues diagnosed within 30 minutes.

Key differentiators include:

- Two-hour arrival windows honored 99.3% of the time

- Certified specialists trained in customer service protocols

- Post-service follow-ups within 48 hours

This approach maintains operational continuity while fostering long-term partnerships. When minutes matter, adaptable scheduling paired with technical mastery delivers measurable results.

Proven Reliability Through Customer Testimonials

Businesses thrive when their partners deliver measurable results—a truth reflected in client experiences across Fayetteville. Verified reviews showcase how technical expertise transforms equipment challenges into operational victories.

Voices That Build Trust

Local restaurant owner Jamie T. shares: “Their team diagnosed our walk-in cooler issue within minutes during dinner rush. Same-day diagnostics saved $1,200 in spoiled inventory.”

A property manager reported:

“Five units needed washer fixes before tenant move-ins. They completed all repairs in one visit with upfront pricing—no surprises.”

| Customer Type | Service Highlight | Resolution Time |

|---|---|---|

| Bakery | Oven thermostat replacement | 2.5 hours |

| Apartment Complex | Multi-unit dryer vent cleaning | 4 hours |

| Homeowner | Refrigerator compressor fix | Same-day |

Commercial clients praise consistent quality across equipment types. One hotel chain noted 43% fewer service calls after switching to preventive maintenance plans. Residential users highlight respectful technicians who explain complex fixes simply.

Fair pricing remains a recurring theme in feedback. A recent review states: “No upselling—just honest solutions from the Fayetteville appliance repair team.” This alignment of value and expertise fuels 94% customer retention rates.

These accounts demonstrate how operational trust grows through repeated excellence. When systems falter, proven performers restore confidence along with functionality.

Enhancing Appliance Longevity Through Regular Maintenance

Operational efficiency hinges on consistent performance, making proactive care a strategic priority. Simple routines can prevent 73% of common malfunctions, according to service data from commercial clients. Businesses that prioritize scheduled upkeep reduce operational disruptions while optimizing energy use.

Essential Maintenance Tips for Long-Lasting Units

Clean refrigerator coils quarterly to prevent compressor strain. For washing machines, inspect hoses annually for cracks and replace every five years. Dryers require monthly lint trap cleaning and duct inspections to avoid fire risks.

Dishwasher filters need weekly rinsing to maintain water flow. Gas ovens benefit from burner calibration checks every six months. “Minor adjustments during slow periods prevent major headaches later,” advises a technician with 15 years’ experience.

Wellness Programs to Prevent Future Issues

Customized maintenance plans address specific usage patterns. Quarterly inspections track wear in high-stress components like dishwasher pumps or washer drum bearings. Clients report 40% fewer breakdowns after enrolling in these programs.

Key program features include:

- Priority scheduling for urgent follow-ups

- Discounted rates on parts for enrolled units

- Digital health reports tracking performance trends

Preventive care extends equipment lifespan by 2-4 years on average. This approach transforms maintenance from reactive fixes to strategic asset management, protecting both productivity and budgets.

Commitment to Service Excellence and Warranty Assurance

Trust forms the foundation of lasting business partnerships, especially when equipment performance impacts daily outcomes. Our warranty programs and quality protocols ensure clients receive dependable solutions that stand the test of time.

Guaranteed Parts and Labor for Every Repair

Every service includes a 12-month warranty covering both components and workmanship. Technicians use manufacturer-approved parts from brands like Whirlpool and Samsung, ensuring compatibility and durability. “We refuse to compromise on materials—it’s why 97% of our repairs last beyond warranty periods,” states a lead specialist.

Rigorous quality checks involve dual inspections before closing work orders. Service records show 94% customer satisfaction rates over five years, with repeat calls dropping 62% after warranty implementation. Clients appreciate transparent policies that eliminate hidden fees.

- Factory-certified components meet strict performance benchmarks

- Real-time job tracking provides visibility into repair stages

- Multi-point testing verifies operational safety post-service

The experienced team resolves issues efficiently while prioritizing long-term reliability. Whether addressing dryer malfunctions or complex system errors, clients gain peace of mind knowing solutions endure. Excellence isn’t promised—it’s guaranteed.

Conclusion

Building lasting business resilience starts with dependable technical alliances. Professional appliance repair services minimize downtime through rapid response times and precision diagnostics. Trusted partners deliver same-day solutions for urgent issues, whether addressing refrigerator repair needs or washing machine malfunctions.

Preventive maintenance programs extend equipment lifespan while optimizing daily performance. Local expertise in Fayetteville and surrounding areas ensures technicians understand regional operational demands. Businesses gain predictable costs and reliable water-tight solutions.

Choosing expert Fayetteville appliance repair specialists translates to measurable results: fewer disruptions, lower long-term costs, and enhanced productivity. Schedule a service call today to secure operational continuity with professionals who prioritize your success.

Dedication to excellence remains our cornerstone. From initial assessment to post-service follow-ups, every interaction reinforces our commitment to customer satisfaction and equipment reliability.